Infrastructure

Leading the Market in Quality, Innovation, and Timely Deliveries”

FACILITES

- Special care for food packaging, which can meet the cleanliness & hygenic environments.

- Decorating facility includes screen printing ., heat transfer labels, in-mold labels etc.

- Sister consent copmany manufacturing of heat transfer labels & in-mold labels.

- Well experienced skilled and qualified manpower.

- Well equiped lab with various testing facility for incoming material, inprocess and finished goods .

- Our products are exported to mali & ivory coast.

INFRASTRUCTURE INCLUDES :

- Having 24 injection molding machines with capacity from 100 tons to 550 tons.

- Processing various polymers like ppcp, lldpe, hdpe. Etc . Having processing capacity of about 300 tons per month, which will increased to about 300 tons with the on going expansion of molding machines , screen printing machines and new molds specially for food industry.

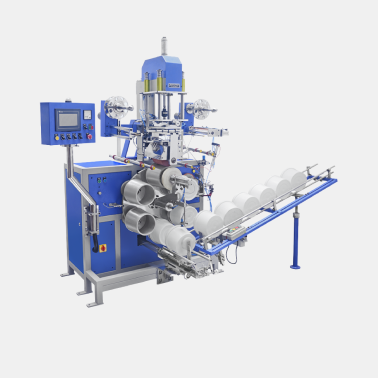

HTL Machine

The HTL (Heat Transfer Labeling) Machine is used for applying pre-printed labels onto plastic containers with precision. It ensures high-quality, durable, and scratch-resistant labeling, enhancing product aesthetics. This technology enables seamless branding without additional adhesive requirements. It is widely used in food, paint, and lubricant packaging.

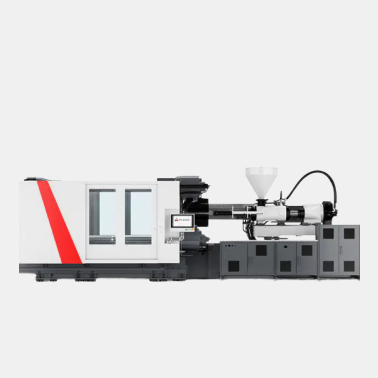

IMM Machine

The IMM (Injection Molding Machine) is the core equipment for manufacturing rigid plastic containers. It injects molten plastic into molds under high pressure, ensuring consistent quality and durability. This machine enables mass production of containers in various sizes. It is essential for high-speed and precision molding.

SP Machine

The SP (Screen Printing) Machine is designed for direct printing on plastic containers. It applies ink with high accuracy, ensuring vibrant and long-lasting prints. This method is widely used for branding and product information. It is suitable for multi-color printing on curved and flat surfaces.

Hot Air Oven

The Hot Air Oven is used for quality testing by simulating heat exposure conditions. It ensures that plastic containers maintain their integrity under high temperatures. This testing is crucial for industries like food and chemicals. The oven operates with uniform heat distribution for accurate results.

VIBRATION TESTER

The Vibration Tester evaluates container durability under simulated transportation conditions. It replicates vibrations encountered during shipping, ensuring the packaging withstands rough handling. This test prevents leakage or breakage issues. It is essential for maintaining product reliability.

LID FITMENT MACHINE

The Lid Fitment Machine ensures proper sealing of containers with tamper-evident lids. It applies uniform pressure to achieve a secure and leak-proof closure. This process guarantees product safety and extends shelf life. It is widely used for packaging paints, food, and chemicals.

MELT FLOW INDEX TESTER

The Melt Flow Index (MFI) Tester measures the flow properties of plastic materials. It determines the viscosity and processability of polymers under controlled conditions. This test ensures raw material consistency for injection molding. It is critical for maintaining product quality and performance.